Technology innovation and advance LEDs for airfield lighting

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 8 December 2011 | Jennifer Taylor, Lighting Research Centre, Rensselaer Polytechnic Institute, Troy, N.Y. | No comments yet

In the past two decades, the LED (light-emitting diode) has advanced to the point where it is now considered a key lighting technology, not only for its potential to save energy, reduce carbon emissions, and have a long service life, but also for its ability to be ‘tuned’ for optimal visual perception. For airfield lighting applications, technology performance and perception are equally important. In terms of technology performance, energy savings is a significant feature, but so too are the durability and longevity of the lighting system, which may have to operate under extreme weather conditions. In terms of visual perception, a lighting system’s light output, intensity, spectral distribution, and spatial and temporal beam distributions all affect the system’s salience and a pilot’s ability to perceive the light.

Because LED light sources – semiconductors that emit photons – are inherently different from incandescent light sources, their performance and perception do not match those of incandescent lamps. Therefore, before LED lighting can replace incandescent lighting on airfields, two steps must be taken. First, it is crucial to determine whether LED systems can provide equal or greater technology per – formance and visual perception, in order to ensure safety, optimal life-cycle cost savings, and maintenance schedules. This step involves multiple levels of research, both in the laboratory and in the field, and should be conducted for many different types of airfield lighting applications and light source colours. Second, airfield lighting standards must be reviewed and changed as necessary to accommodate LED lighting systems, since existing standards were written with incandescent technology in mind. This step may involve changing fixture design requirements, such as thermal management system components or allowable light source colour boundaries and intensity levels, per research findings.

In the past two decades, the LED (light-emitting diode) has advanced to the point where it is now considered a key lighting technology, not only for its potential to save energy, reduce carbon emissions, and have a long service life, but also for its ability to be ‘tuned’ for optimal visual perception. For airfield lighting applications, technology performance and perception are equally important. In terms of technology performance, energy savings is a significant feature, but so too are the durability and longevity of the lighting system, which may have to operate under extreme weather conditions. In terms of visual perception, a lighting system’s light output, intensity, spectral distribution, and spatial and temporal beam distributions all affect the system’s salience and a pilot’s ability to perceive the light.

Because LED light sources – semiconductors that emit photons – are inherently different from incandescent light sources, their performance and perception do not match those of incandescent lamps. Therefore, before LED lighting can replace incandescent lighting on airfields, two steps must be taken. First, it is crucial to determine whether LED systems can provide equal or greater technology per – formance and visual perception, in order to ensure safety, optimal life-cycle cost savings, and maintenance schedules. This step involves multiple levels of research, both in the laboratory and in the field, and should be conducted for many different types of airfield lighting applications and light source colours. Second, airfield lighting standards must be reviewed and changed as necessary to accommodate LED lighting systems, since existing standards were written with incandescent technology in mind. This step may involve changing fixture design requirements, such as thermal management system components or allowable light source colour boundaries and intensity levels, per research findings.

In the United States, the Federal Aviation Administration (FAA) has been investigating the use of LEDs to replace incandescent light sources for lighting airfields. In 2005, the FAA’s research and development division asked the Lighting Research Centre (LRC) at Rensselaer Polytechnic Institute to join the FAA’s Centres of Excellence programme to help its team understand the issues involved with trans – itioning to LED-based airfield lighting in terms of both technology performance and visual perception as it compares with the incumbent incandescent technology. Since then, the LRC has applied its expertise in LED technology, vision science, and human factors research to the task, studying LEDs for taxiway lighting, remote airfield lighting, and runway guard lights, as well as colour and intensity issues based on human visual performance rather than the limits of incandescent lamp performance. Several of these studies were described in Issue 5, 2010 of International Airport Review. I will outline two studies completed recently.

Optimising LED-based elevated runway guard lights for improved visual performance

Runway guard lights, which help pilots detect the presence of taxiway/runway intersections, are one airfield lighting application that the LRC has investigated for possible use with LEDs. In a multiple-stage research project, LRC scientists conducted laboratory and field studies to understand the influence and inter – action of different lighting parameters on the visibility of elevated-type runway guard lights (ERGLs) to pilots.

Laboratory study

In 2008, the LRC designed a psychophysical laboratory study to investigate both incan – descent and LED-based ERGLs to determine first the minimum luminous intensity (brightness) required by incandescent-based ERGLs, and second, whether LED-based ERGLs can be optimised for better conspicuity than incandescent models while using a lower intensity, and thus less energy. Under three simulated environmental conditions (daytime, night time, and foggy daytime), LRC scientists collected reaction times and conspicuity data from subjects who viewed simulated ERGLs in a scaled down airfield built in the lab. During the experiments, LRC scientists modified the simulated ERGLs’ luminous intensity, duty cycle, and flash rate. The subject data was then used to define minimum intensity requirements and the best combination of intensity, duty cycle, and flash rate for conspicuity of LED-based ERGLs.

The results from the laboratory study showed that for the three environmental conditions tested, the existing minimum luminous intensity requirements are sufficiently noticeable to pilots; therefore, the LRC concluded that for incandescent-based ERGLs, the intensity requirements should not decrease. However, using the right combination of flash rate, duty cycle, and waveform shape, the intensity of LED-based ERGLs could be reduced by about two thirds from current recommended values2.

Field Studies

Using the findings from the laboratory study in 2010, LRC scientists together with the FAA Technical Centre staff designed a field experiment to be conducted at Schenectady County Airport in Glenville, N.Y. This second stage of the research project tested at an actual taxiway/runway intersection the most promising combinations of flash rate and duty cycle with the intensity of the LED-based ERGLs reduced to one third compared with the incandescent. Under ideal circumstances, pilots should readily notice the ERGLs but not be overly distracted by them. In the field experiment, subjects viewed prototype LED-based ERGLs during clear visual conditions from a moving truck that simulated a small taxiing airplane. Subjects rated each ERGL operating combination for its ‘noticeability’ and its ‘distraction’.

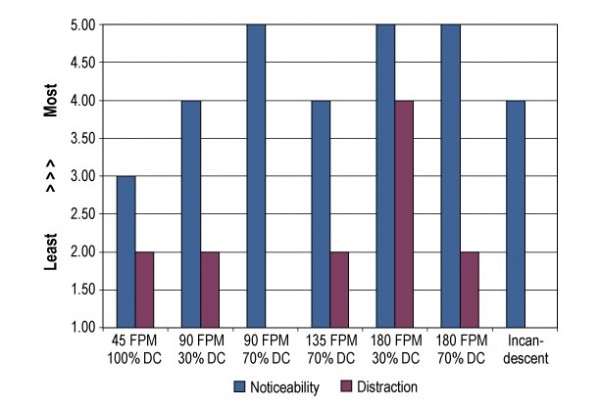

Figure 1 shows the median noticeability and distraction ratings for selected flash rate (FPM) and duty cycle (DC) combinations tested at the Schenectady County Airport. The ERGLs at 90 FPM and 70 per cent DC showed the highest noticeability with minimum distraction at intensity values less than 30 per cent of the incandescent base case3. The results from the Schenectady County Airport field experiment confirmed the findings from the laboratory study that at a suitable flash rate and duty cycle, LED-based ERGL intensity can be reduced by two thirds without affecting visibility or conspicuity. Using the operating combination that provided the best noticeability and the least distraction, a manufacturer of airfield lighting systems built prototype LED-based ERGLs according to the LRC’s specifications at the FAA Technical Centre’s request. These prototypes were used in the final stage of the research.

FIGURE 1Median noticeability and distraction ratings for selected flash rate (FPM) and duty cycle (DC) combinations tested at the Schenectady County Airport.

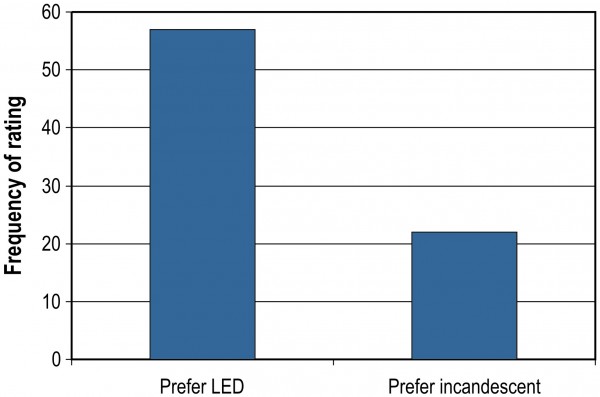

In 2011, the FAA funded Embry-Riddle Aeronautical University to conduct the final research stage – a large field evaluation to validate the LRC’s laboratory and field findings. Embry-Riddle researchers used the prototype LED-based ERGLs to study pilots’ perceptions during runway operations at Daytona Beach International Airport, a major airport in Florida. During the hold short operation, pilots were asked to rate the brightness, noticeability, and distraction of both LED and incandescent ERGLs and to state their preference for one over another. Surveys gathered from 86 pilots of all experience levels under different environmental conditions showed that pilots perceived the LED-based ERGLs to be brighter and more noticeable than the incandescent models. Statistical analysis of the preference question determined that pilots preferred the LED runway guard lights over the incandescent versions1. The results are shown in Figure 2.

FIGURE 2 Statistical analysis showed that pilots at Daytona Beach International Airport, Florida preferred the LED-based ERGLs over incandescent lights4

These results signify that a properly designed and built LED-based ERGL is as effective as or better than current incandescentbased ERGL in alerting pilots. Additionally, LED-based systems have the potential to be less expensive to use and maintain as a result of lower power demand and longer service life.

Technology innovation for better reliability from LEDs

The amber/yellow LEDs used in ERGLs can provide effective visual guidance to pilots, as the previous study showed. But is the amber light source’s operating performance also sufficient for use on airfields? That question was the premise for a study investigating the performance differences among materials used to create amber LEDs.

High-powered LEDs fall into two material categories. Indium, gallium, and nitride materials (InGaN) are combined to create blue and green direct-emission LEDs, while aluminum, indium, gallium, and phosphide materials (AlInGaP) are combined to create red, orange, and yellow direct-emission LEDs. Compared with InGaN-based LEDs, AlInGaPbased LEDs are much more sensitive to heat. High temperatures are known to cause color shift and reduce the light output and life of LEDs made of this material combination. Over time, direct-emitting amber AlInGaP LEDs in some airfield lighting applications could show poor operational performance.

hite light LEDs are made by combining an InGaN-based LED with a rare earth phosphor. When the blue photons reach the phosphor coating, the phosphor converts the blue light to white before it is emitted. This method, called phosphor conversion, has been well researched, and the phosphor-converted LED (pc-LED) is the most common means of obtaining white LED light. However, the creation of colours other than white through the phosphor conversion method has not been well understood. Because InGaN-based LEDs are more thermally stable and thus more desirable for use in airfield lighting applications, there is a great advantage to creating an amber pc-LED through the proper combination of a blue LED chip and a suitable phosphor. In this study, the LRC investigated and compared the impact of heat on both traditional, direct-emission amber LEDs and prototype amber pc-LEDs.

LRC researchers developed in the lab amber pc-LEDs using a commercially available InGaN blue LED and two different commercially available phosphors. Phosphor ‘recipes’ were tested and improved to create two different prototype amber pc-LEDs with the best efficiency possible and with a yellow color meeting aviation lighting standards. One by one, the prototype amber pc-LEDs and a commercial direct-emitting amber LED were placed in a heating chamber and subjected to increasing levels of heat. The circuit board temperature of each LED (a good predictor of reliability and life) along with light output and color shift were measured at each level of temperature increase.

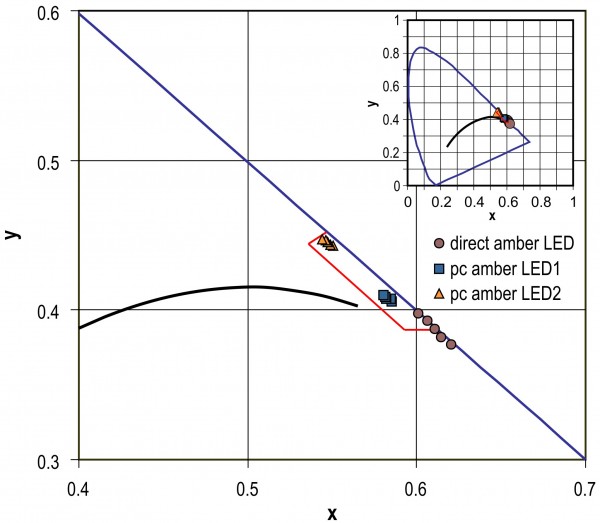

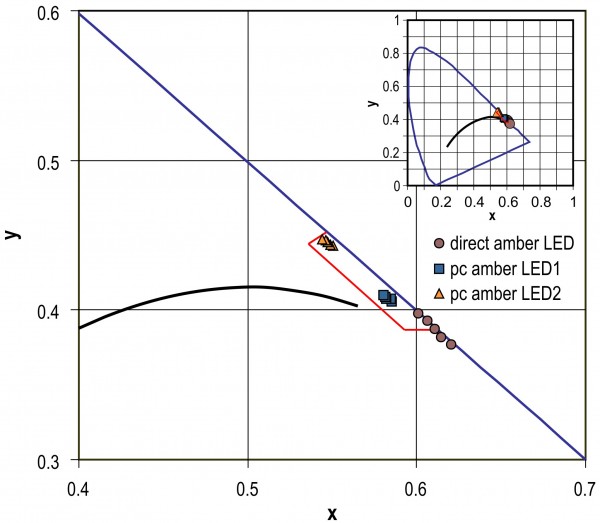

The results showed that at each board temperature increase, the amber pc-LEDs were better at maintaining their light output (lumen maintenance) than the traditional directemitting amber LED. The amber pc-LEDs also showed much less color shift with increasing temperature than the direct-emitting amber LED. An additional benefit of the amber pc-LEDs is a much higher initial light output, meaning greater efficiency and energy savings. See Figure 4 and Figure 3.

FIGURE 3 Light output as a function of increasing board temperature for a commercial directemitting amber LED and for two prototype phosphor-converted amber LEDs created at the LRC. The prototype amber pc-LEDs showed higher initial light output and better lumen maintenance, meaning greater energy efficiency even at higher temperatures. The direct-emitting amber LED is much more sensitive to heat, showing a significant light output decline when heated from 40°C to 80°C4

FIGURE 4 Color shift as a function of increasing board temperature for a commercial direct-emitting amber LED and for two prototype phosphor-converted amber LEDs created at the LRC. The prototype amber pc-LEDs showed much less color shift, meaning the yellow color is more likely to stay within standard aviation color boundaries when the application temperature is high. The direct-emitting amber LED is much more sensitive to heat and its color may shift outside the standard color boundary, as shown above (Zhang, 2011).

LED lighting for U.S. airfields is moving forward

These studies and other research now in progress are helping both lighting scientists and aviation specialists to understand the best means of successfully implementing LEDs in airfield lighting applications. LED lighting research is a work in progress, and many organisations around the world are investigating ways to improve LED technology performance and the visual perception of LEDs. One group, the Alliance for Solid-State Illumination Systems and Technologies (ASSIST), will celebrate in 2012 its tenth year of LED lighting research, education, and demonstration. This industry group organised by the LRC, of which the FAA is a member, has sought to overcome the technical and market barriers to LED lighting.

For more information about airfield lighting research, visit the LRC’s aviation research page at www.lrc.rpi.edu/researchAreas/aviation.asp. For more about ASSIST, visit www.lrc.rpi.edu/assist.

References

1. French, J., H. Greenfield, R. Bassey, and D. Gallagher. 2011. Pilot awareness of current and LED elevated runway guard lighting (ERGL). Proceedings of the 10th Annual Meeting of the Centre of Excellence for General Aviation Research, Daytona Beach, FL, May 24-26.

2. O’Rourke, C., and L. Radetsky. 2008. Psychophysical laboratory testing to evaluate elevated runway guard lights. Final report to Federal Aviation Administration for contract FAA/05-C-AT-RPI, July 15, 2008, Lighting Research Centre, Rensselaer Polytechnic Institute, Troy, N.Y.

3. Skinner, N.P. 2010. Field evaluation of various elevated runway guard light configurations. Final report to Federal Aviation Administration for contract FAA/05-C-AT-RPI, December 15, 2010, Lighting Research Centre, Rensselaer Polytechnic Institute, Troy, N.Y.

4. Zhang, W. 2011. Impact of heat on the light output and chromaticity of direct-emitting and phosphorconverted amber LEDs. Master’s thesis, Lighting Research Centre, Rensselaer Polytechnic Institute, Troy, N.Y.

About the Author

Jennifer Taylor, MSc, is a Senior Communi cations Specialist for the Lighting Research Centre at Rensselaer Polytechnic Institute, Troy, New York, since 2003. She works primarily in the field of solid-state lighting and LEDs, and has worked with the LRC’s solid-state lighting team to produce lighting test methods, application guidelines, journal articles, research summaries, and other publications about LED lighting technology.