Cargo focus: IATA’s 5 ways to optimise low automation operations

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 11 May 2017 | Ricardo Aitken | IATA | No comments yet

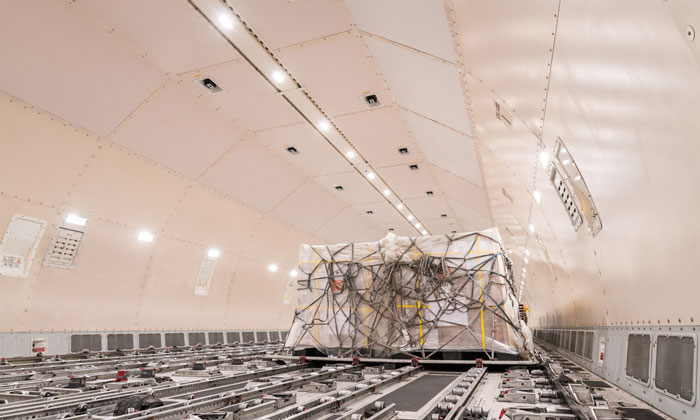

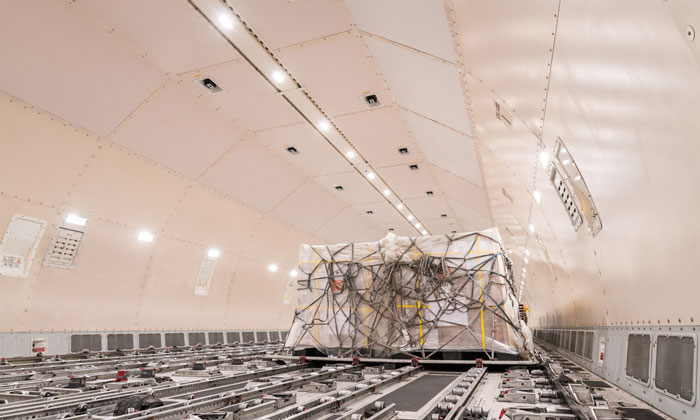

Cargo terminal optimisation for manual/low automation operations as told by IATA’s Ricardo Aitken.

Optimising cargo operations is important but far from straightforward. Here are Ricardo Aitken’s five key ways to ensure success…

#1 Do a management walkthrough

Cargo Terminal Operators (CTO) managers and executives should consider undertaking unannounced walks around their facilities from time to time to observe operations and speak with staff. Not only does this provide an honest assessment of operations, it also gives management visibility with front line staff, helps reduce any disconnect between personnel reports and reality, and effectively change behaviour by leading through example.

#2 Conduct a racking optimisation study

Storage racking plays a key role in any cargo terminal operation. Quite often, the existing racking units have outlived their original design and purpose. As a result the full available height of the warehouse might be not properly utilised to maximise the available floor space. New forklift types might be needed, but a fit-for-purpose racking study can determine the benefits and costs of transforming the racking area to gain additional vertical and horizontal storage space.

#3 Schedule receiving appointments at the dock

An easy way to manage arrival rate fluctuation is to schedule delivery appointments for all inbound shipments. CTOs can assign a specific time (or window of time) for delivery on a carrier or shipment basis. Alternatively, depending on the amount of cargo handled, a recurring schedule (daily, weekly or monthly) could be assigned. This allows for better personnel and equipment scheduling particularly when combined with advanced paperwork requirements. It will minimise overcrowding the limited available dock space and will reduce “surprises” (e.g. when odd size cargo or very large shipments unexpectedly arrive).

#4 Forecast!

Do not underestimate the power of a good forecast. CTOs need to understand market challenges, key market drivers, demand patterns, stakeholder activities and intentions as well as major market trends if they want retain clients and attract new revenue. A good forecast will provide CTOs with business requirements and knowledge of how much space/equipment (both quantity and type) will be needed to better meet the expectations of their current/future clients. A solid forecast will help avoid reactive growth to the expected/planned mix of commodities.

#5 Do not to forget safety

It is good to reward on-time performance (OTP) and overall throughput but warehouse safety should be the top priority. There are ever increasing health, safety and ergonomics regulations but unfortunately too many warehouses only seek to meet the minimum mandated by law citing insufficient time, cost or inadequate resources. In the long run, however, a safety oriented work culture will deliver savings due to fewer disruptions, reduced equipment/personnel downtime, extended life of infrastructure (e.g. racking) and higher employee satisfaction and productivity.

Got your attention? Good. Find out 21 tips to optimise low automation operations at a cargo terminal coming very soon…

Ricardo Aitken is a project manager in the Consulting Division of the International Air Transport Association (IATA). He is responsible for projects in the areas of:

- Air Cargo / Ground Handling – Business Planning and Infrastructure Development

- Air Cargo / Ground Handling – Operations and Logistics

Before joining IATA, Ricardo worked at Lufthansa Consulting, a world-class German aviation and management consulting firm, as a consultant to diverse projects across the globe.

Mr. Aitken has worked on-site for projects in Australia, Brazil, Cambodia, Djibouti, Ecuador, Germany, Japan, Kazakhstan, Luxembourg, Rwanda, Saudi Arabia, Thailand and Trinidad.

Mr. Aitken has four engineering degrees.