Working to a more overall pavement surface friction assessment

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 8 December 2014 | Belkacem Laïmouche, French Civil Aviation Technical Center

To ensure airfield safety, aerodromes should work towards a more overall pavement surface friction characteristic assessment, says Belkacem Laïmouche, Head of the Airfield Pavements Subdivision at the French Civil Aviation Technical Center.

The pavement friction level is one of the leading security areas an airport must address and maintaining the level in acceptable condition requires an overall friction characteristics assessment. It is clear that the practices of European Union (EU) member states in this field differ from one country to another which ultimately means passengers are being provided with varying security levels depending on their destination.

This is precisely the reason the EU has undertaken harmonisation rules on the safety of civil aviation on a European scale. As such – and under the European Aviation Safety Agency (EASA) Basic (EC) No 216/2008 Regulation – the European Commission (EC) has issued detailed regulations for certification on aerodromes1 entitled ‘Party Authority, Organization and Operations Requirements for Aerodrome’. The EC relies on this settlement to make Implementing Rules (IR), which specify the basic requirements that must be met by airport operators.

The Basic Regulation empowers the EASA to develop three different types of ‘soft law’. Published on 12 February 2014, Acceptable Means of Compliance and Guidance Material (AMC-GM) and Certification Specifications and Guidance Material (CS-GM) are respectively a means of meeting the intent of the associated IR and a technical standard to meet the essential requirements of the basic regulation (BR). By meeting the published AMC, this demonstrates compliance with the IR. CSs are used to establish the certification basis (CB).

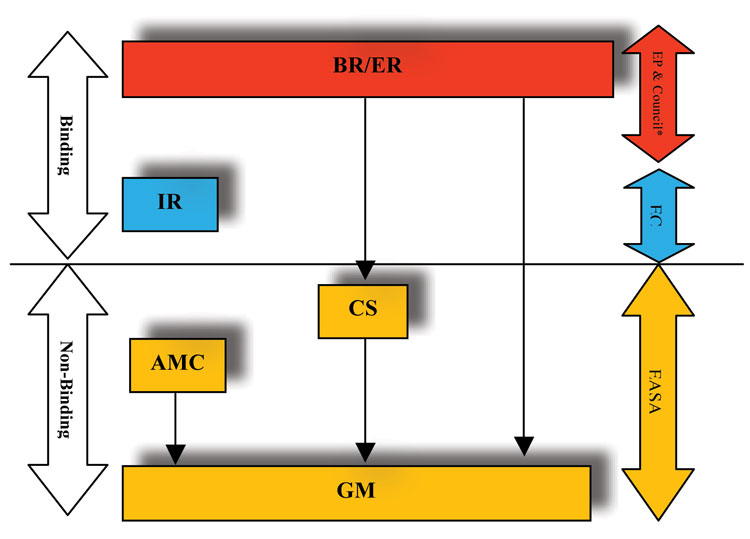

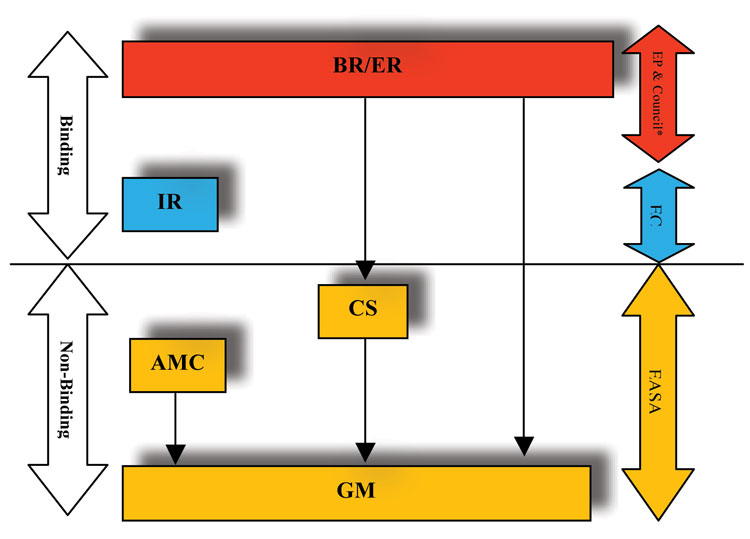

Should an aerodrome operator not meet the recommendation of the CS or AMC, they may respectively propose an equivalent level of safety or an alternative means of compliance that demonstrates how they meet the intent of these standards (Figure 1).

Figure 1: European regulatory framework

If the objective of the European requirements is notably to further enhance safety of aircraft surface movement operations, their enforcement may profoundly change the practices of some states; requiring them to fully implement the measures by removing the conflicting national practices.

After presenting the stakes of runway surface friction characteristic monitoring, this article will propose to make a brief analysis of the AMC/GM and CS/GM with regards to pavement surface friction characteristics enhanced by discussions held in France to propose ways for a better appropriation of these non-binding standards on some points.

Principles of runway surface friction characteristic monitoring

‘Surface friction’ means the resistance offered to the movement of one body past a surface with which it is in contact. In the aeronautical or road field, we often symbolise it by the Greek letter µ or by the acronym LFC (Longitudinal Friction Coefficient).

The LFC depends on pavement surface conditions, on an aircraft’s operating speed and the condition of the aircraft tyres, such as wear and pressure. The value is usually between zero and one. A value of zero means there is no friction between the tyre and the runway surface. A value of one means the frictional force is equal to the weight of the aircraft. In other words, to ensure good aircraft safety a pavement’s surface must not have a low LFC.

Tyre pavement friction is dominated by the texture, or roughness, of the surface, with different texture components making different contributions:

- The micro-texture: it provides pavement friction at low speeds

- The macro-texture: it reduces potential for hydroplaning and provides friction by hysteresis at high speeds.

In order to evaluate the runway friction, it is obligatory to use a Continuous Friction Measuring Equipment (CFME) device.

Technique for runway surface friction measurements

A runway surface friction assessment is conducted under controlled conditions using self-wetting CFME devices, to establish the friction characteristics of a runway and to identify those areas of a runway surface that may require maintenance actions for safe aircraft operation. Friction readings for the survey run are collected along the line of the entire pavement length.

In accordance with ICAO Annex 14, these tests must be conducted at 40.4 and 59mph respectively to have a ‘sense’ on the micro- and macro-texture of the runway surface. Several technologies exist and are commonly used across the world. The result of the measure is used to assess the ability of an aircraft to brake in a straight line during wet weather.

Friction monitoring for reducing the risk of runway excursion in wet conditions

Runway excursions are among the most common event categories of accidents in air transport operations and can impact economic activity in a region.

To allow aircraft to operate safely, it is necessary to periodically evaluate the state of pavement deterioration, especially the friction of the runway. According to the EASA’s 2013 safety review “there were 100 runway excursion accidents and serious incidents at EASA aerodromes between 2008 and 2012”. If most runway excursions are caused by improper approaches that lead to aircraft control issues after touchdown, friction pavement conditions are often a contributing factor and if you monitor it through CFME devices measurement, a runway excursion might be avoided.

According to EUROCONTROL, around 24,000 flights are carried out daily in Europe. Because runway operability can condition an airport operation, especially if it has only one runway, it is important to monitor the runway friction to prevent the risk of runway excursion which could have serious consequences at economic level (e.g. paralysis of air traffic). This also depends on the downtime of a runway and the function of the airport itself. For example, if it is a ‘hub’ airport, the consequences can be more severe and could affect other airports; causing cancellations to flights and thereby slowing the economic activity in a region.

Longitudinal friction coefficient: A pertinent indicator to assist an airport in programming and implementing maintenance actions

In European airports with high aircraft traffic, there is a daily presence of rubber on the runway touchdown zone. These areas usually represent the first and last third of the runway. Thus, most rubber deposits are formed on a very delicate area of the airport runway; namely the landing and take-off area. In wet conditions, these areas may be dangerous for a number of factors:

- The rubber deposits covering the runway surface nullify the effect given by the roughness

- Besides being waterproof, rubber is very slippery and in these conditions furthers the risk of aquaplaning

- The area covered by rubber deposits undergoes an alteration of the water flowing plane that can promote formation of puddles with a further danger for the mechanical operation of the aircraft turbines.

Residual rubber layer after a water degumming operation

Because it is difficult to totally remove rubber deposits with the usual maintenance techniques (e.g. water degumming or shot-peening) and simultaneously pave the ideal friction and roughness values, it is instead recommended to partially remove the rubber deposits. This is why the runway always retains residual rubber deposits (see Figure 2) and his monitoring through repeated friction measurements is a reliable way to alert an airport of the risks for aircraft safety and allow programming of maintenance actions easily.

Figure 3: Pavement grooving

Finally, depending on the roughness of the runway, an airport may also be required to implement maintenance actions aimed at creating a macro-texture such as grooving (Figure 3) or grinding (Figure 4) to control hydroplaning and to ensure adequate friction, especially under wet pavement conditions.

Figure 4: Pavement grinding

There are both security-related and economic stakes involved with pavement friction monitoring. Safe transportation represents a subject of common interest and has recently led to the formation of a regulation across the European Union with binding effect.

A European regulatory framework designed to promote a higher security level

To ascertain the uniform application of IR by European authorities and operators, flexibility has been provided by the EASA through the use of non-binding standards (AMC/GM and CS/GM). A non-exhaustive analysis of these soft laws in relation to friction is examined here.

Technical standards should allow an overall pavement friction assessment

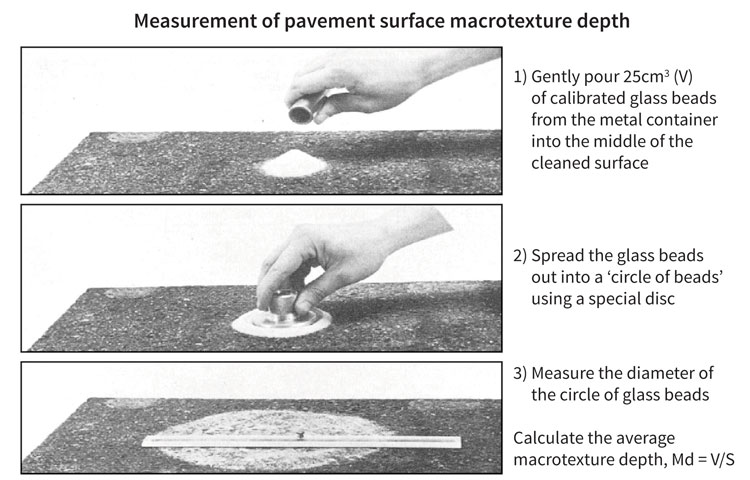

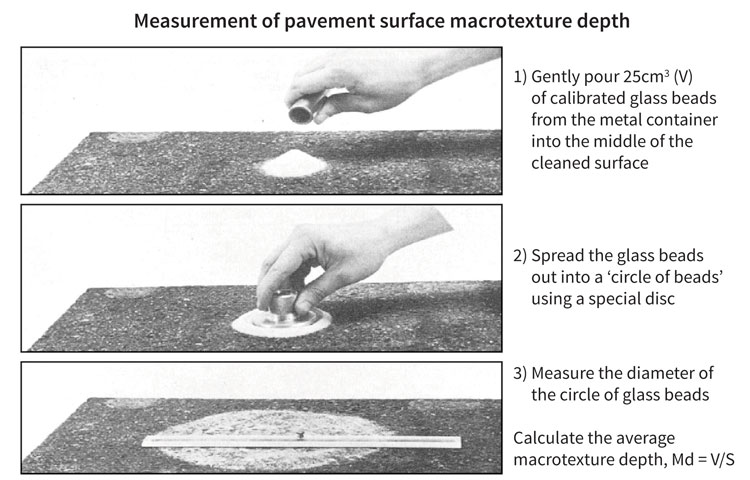

Because of the drainage characteristic affecting the friction coefficient between the aircraft tyre and the pavement surface in wet conditions, airports need to control the texture of a new surface in order to check it provides a good macro-texture. The average surface texture depth of a new surface should not be less than 1mm. Today it is by example through standardised ‘average surface texture depth’ measure2, using a volumetric patch technique (Figure 5) that could guide the control of this ambitious specification.

Figure 5: Measurement of pavement surface macro-texture depth

Source: French Committee of the world road association (Cf-aipCr); Information Memorandum No. 11 March 2005

For road infrastructure, measuring devices like SCRIM (Sideway-force Coefficient Routine Investigation Machine) features an integrated system profilometric laser measurement, for macro-texture assessment, and therefore it would be sensible to encourage CFME manufacturers to explore the possibility of integrating a similar system.

To increase the security of an aircraft’s manoeuvres during rainy weather, it is important to know the friction measurements on all pavements and not just the runway. Friction measurements should be able to be easily performed on runways, but based on a standard test methodology, the friction measurement could be blocked by a lack of appropriate methodologies, for access ramps to the runway, for example. To this methodological difficulty, we can add technical difficulty as CFME is not all adapted for measuring friction in turn areas, for example (as most CFME devices measure a longitudinal friction coefficient, not a transverse friction coefficient) on the runway end safety area (RESA).

It is important also to assess the runway turn pad friction for safer curvilinear motions. The geometric configuration of airfield pavements may require an aircraft to make curvilinear movements (e.g. runway turn pad) and depending on the aircraft speed and friction conditions, the risk of pavement excursion can occur.

RESA, stopways and runway thresholds

Runway areas are not always assessed with CFME devices and could be yet solicited during a landing or braking phase. Because the runway sections on and near the thresholds are also used during landing aircraft, it is important to carry out a good friction assessment to allow an airport to bring, if needed, appropriate maintenance actions (Figure 6). You would assume it’s still necessary for the runway to enable CFME devices to fully measure a friction surface, but this is not always the case. Indeed, analysis of the runway friction database created by the Civil Aviation Technical Center (STAC) pavement division over the past three years – from auscultation measurements on aeronautical runways – shows that in some configurations the first and the last hundred yards of a runway are not always measured because of:

- The need for acceleration/braking to allow respectively reaching high speed (59mph) and the safe braking of the CFME devices

- To a lesser extent, by the reaction time of the various sensors of a CFME devices to allow measurement at nominal speed.

As in other countries, in France pavement excursions over recent years were recorded and, as mentioned in some accident investigation reports, the surface friction remains one of the explanatory causes. Because there is a good probability of pavement excursion during wet conditions, particularly on the turn areas of the runway, it is necessary to consider appropriate auscultation methods.

Figure 6: Rubber deposits on runway thresholds due to landing aircraft

As EASA standards lead to an overall friction pavement assessment, STAC investigated what extent the CFME devices can meet various indicators of friction (e.g. the macro-texture) and what adaptations/developments to make in addressing these requirements.

In this framework, STAC has conducted a literature study to identify and evaluate the performance of CFME devices measurement and practices in the road sector. This study required a year of work, a survey of owners of CFME devices and industrial and analysis of a database compiled since 2006 from friction measurements made by different types of devices, has resulted in the identification of several development opportunities. Among them, a study concerning the correlation measurements made by devices stationary measurements with LFC dynamic devices measurements, inspired of road sector research studies3,4.

Mastering the skill of personnel; ensuring quality in airport operations

The need for qualified personnel acting directly or indirectly on the infrastructure for such surveillance operations helps to preserve the level of aerodrome safety. Thus the European ADR regulation requires an aerodrome to implement a system of management “that covers all staff involved in the operation, maintenance, and management of the aerodrome (supervisors, managers, senior managers, and the accountable manager”.

With this awareness at European level, and given the security stakes, we hope recognised providers are encouraged to perform maintenance actions and control with regard to friction measurements. To this end, in France the STAC and Aéroports de Paris (ADP) have shifted in recent years towards the establishment of a management system for robust quality to master the skills of their personnel performing friction tests, ensuring to their respective clients the quality results of their tests. One of the recognised ways to meet this objective could be – as is the case with STAC and ADP – the establishment of a certification in accordance with ISO/IEC 17025 standard5.

In this perspective, DSAC (France’s National Supervisory Authority) which is concerned with data quality monitoring runway friction, was employed (with the help of STAC) to better control the service provider’s skills. It is through inter-comparison tests, organised according to the ISO/IEC 17043 standard6, that STAC periodically evaluated the ability of laboratories to carry out a friction measurement.

If successful, an approval certificate is issued for a term of two years. Also, it is after this proficiency testing that, in France, according to the international standard ASTM E2100-045 and from robust statistical tests, it is carried out to the connection between STAC International Reference Vehicle (IRV) device and different CFME technologies7; ensuring the traceability of the friction measurements and allowing in addition to meet EASA AMC standards with regards on CFME use.

Although the EASA does not currently recommend this more proactive approach, in France it brings with it a higher level of security. Solicitous to contribute for improving the European aerodromes safety, the STAC will be promoting this point to the EASA and relevant authorities, which will perhaps allow a homogeneous and uniform application throughout the EU.

Conclusion

The entry into force of the EASA Aerodrome Certification Requirements, particularly with regards friction and in general about skills and qualifications, encourages thinking respectively to an adaptation of our inspection methods and to a minimum mastery of basic skills needed to control pavement friction.

We sought to determine whether the stationary friction measurement could replace or complement the LFC dynamic measurement. Discussions are being conducted in France in order to establish for stationary measurement devices such as the Skid Resistance Tester (SRT) pendulum, a list of ‘aeronautical’ specifications in addition to the NF EN 13036-4 standard8. Assuming the development of specifications, another major difficulty seems to lie in the use of this type of device that requires skills confirmed but also, for some of them, to a lack of traceability methods of friction measurements.

There is also a pressing need for a continued harmonisation work regarding static measurement in order to better accomplish achieve acceptable specifications of pavement friction area and to facilitate comparisons with the CFME devices at different friction surfacing level. The STAC is continuing its work to allow the construction of a repository of traceability robust measures. Therefore, it would seem premature that nationally, the legislator can now regulate the only use of stationary measurement devices to determine the LFC or the average surface texture depth of a pavement surface. They could find a use for friction assessing in places that do not allow traditional LFC dynamic measurement (e.g. stopways, runway turn pad) or in places a singular runway levels with very low LFC in a context of a further investigation.

Generally speaking, it is necessary to become familiar with EASA rulemaking structure and the legal structure of the requirements. Compliance with these requirements, before the deadline, could involve considerable investments of time and resources to proceed with the necessary work at the conversion of existing aerodrome licences to certificate issued in line with European rules.

References

- EASA website:https://www.easa.europa.eu/regulations

- NF EN 13036-1 September 2010: Road and airfield surface characteristics-Test methods-Part 1: measurement of pavement surface macrotexture depth using a volumetric patch technique – Caractéristiques de surface des routes et aérodromes

- Dynamic Friction Tester (DFT) First French experimentation–RGRA 2013-http://www.editions-rgra.com

- International Experiment to Harmonise Longitudinal and Transverse Profile Measurements and Reporting Procedures (EVEN)–AIPCR 1992 – http://www.piarc.org/

- ISO/IEC 17025:2005, General requirements for the competence of testing and calibration laboratories

- ISO/IEC 17043: Conformity assessment – General requirements for proficiency testing

- Comment assurer la traçabilité dans les cas difficiles ? – Guide technique 2014 – http://cfmetrologie.com/

- NF EN 13036-4 March 2012: Road and airfield surface characteristics – Test methods – Part 4: method for measurement of slip/skid resistance of a surface: the pendulum test – Caractéristiques de surface des routes et aéroports